We Are Victory Fab & Powder Coat

Reliable Metal

Pretreatment & Protection

When you need a job done right the first time, you need Victory Fab & Powder Coat. Based in Rathdrum, Idaho, our reputation is based on quality and professionalism. Being a small, family-owned business allows us the ability to maintain and adhere to strict quality control standards, building a growing book of new and repeat customers. We have extensive experience in powder coating and sandblasting all sizes and types of parts, from one-off custom jobs to large batch processing.

About Us

Meet Scott & Deni

Victory Fab & Powder Coat came together in 2021 as the husband-and-wife team of Scott and Deni sold their 27-year franchise... and, it began with metal signs.

After working with their local Pacific Northwest community for ...

What is

Powder Coating?

Powder Coating is a metal finishing technology to protect and/or provide color and/or texture to metal decorations, parts, and more.

Available in almost a limitless array of colors and textures, performance technological advances have made powder coating a far superior option to painting. A dry finishing process, over 15% of the total industrial finishing market utilizes powder coating on an array of products. The high-quality, durable finish allows for improved efficiencies, maximized production, and even environmental compliance.

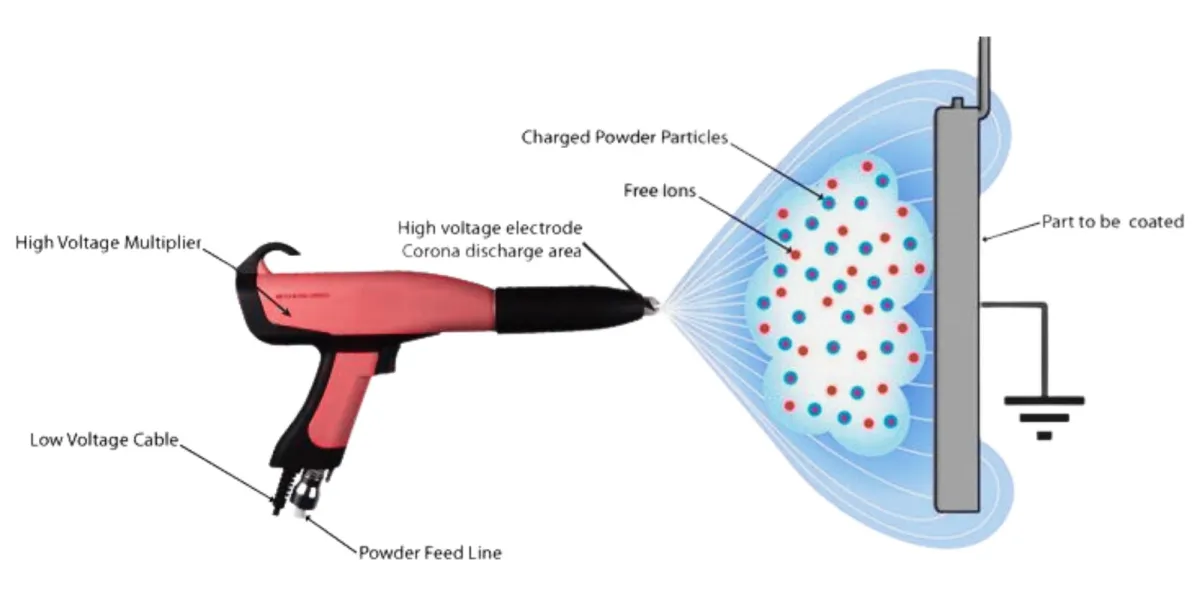

How It Works

The most common powder coating application process is environmentally friendly, cost effective, and provides maximum protection.

First, the metal item is pre-treated to prepare the surface for maximum adhesion. Then, the powder polymer resin is combined with a variety of ...

Pre-Treatment

Prior to powder coating, all items must be pre-treated to strip away existing corrosion or existing coating, as well as to clean, degrease, and outgas the bare metal. The result is a surface finish that is primed to receive the powder coating.

We use chemical stripping and/or sandblasting ...

Durability

Powder coating is commonly used as a higher quality alternative to traditional wet paints, including spray paint. It offers a more durable finish than paint, while resisting corrosion, scratches, chipping, and the impact of moisture, chemicals, extreme weather, and ultraviolet life. And, it creates a highly decorative finish as well as protecting tough machinery and machine ...

Technologies

Color Palette

At Victory Fab & Powder Coat, we utilize vibrant and high-quality powder coating finishes from premier industry manufacturers to bring your creative visions to life.

Need a custom or matched color?

Let's chat! We will ensure that your projects are done to your specifications and stand out from the rest. We are your trusted partner in bringing your visions to vivid reality.

VS

Our Processes

Quality & Reliability

Powder coating is divided into three categories: thermoset, thermoplastic, and UV curable. While these categories differ in application and execution, they all have this in common: a powder is applied to a surface, which hardens under specific conditions. This creates an even, corrosion-resistant surface coat.

Types of Powder Coating

The three main types are,

- Thermoset

-Thermoplastic

- UV Curable Coatings

At Victory Fab & Powder Coat, we use all three powder types, depending on what the best...

You may be wondering why you need powder coating at all when you can just paint your pieces, but many characteristics of powder coat make it a superior alternative to wet spray paint, including:

Hardness

Also, powder coat is physically harder than wet paint, which makes it more scratch and chip resistant with a higher durability rate.

Adhesion

Powder coat also has a higher adhesion rate than spray paint, partially due to the significant pretreatment. Increased adhesion also means increased resistance to chipping and corrosion

Dry Film Thickness

Powder coat is applied at a thickness of 2-10 mil, determined by the need. (Functional finishes are usually thicker than decorative finishes.) This is 4 to 10 times thicker than the 0.5-1 mil traditional application of liquid spray paint.Corrosion Resistance

Properly applied powder coat far exceeds traditional spray paint's ability to prevent corrosion. Test results show that the lower application thickness for decorative use powder coated items do not show signs of corrosion even after going through salt spray tests for more than 1000 hours - and, thicker functional coatings are even more corrosion resistant.

Flexibility

Powder coat is actually a flexible products, with published test results showing 100-800% elongations before failing! This flexibility also contributes to the resistance to cracking or flaking when the part is manipulated.

Environmental Impact

It's common knowledge that wet paint is flammable, but many people don't know it's also carcinogenic (can cause cancer), and contains Volatile Organic Compounds (VOCs). On the contrary, powder coat is environmentally friendly, as the powder is not a significant health, fire, or environmental hazard. Additionally, the powder is applied when it's dry using an electrostatic bonding process that that allows ~90% of the powder to adhere to the item - and, the remainder falls to the ground to be collected and disposed of instead of going into the atmosphere. Thus, powder coating has a minimal amount of waste. Spray painting efficiency, however, is often below 50% and the paint that doesn't adhere goes into the air or settles onto nearby objects, unable to be reused.

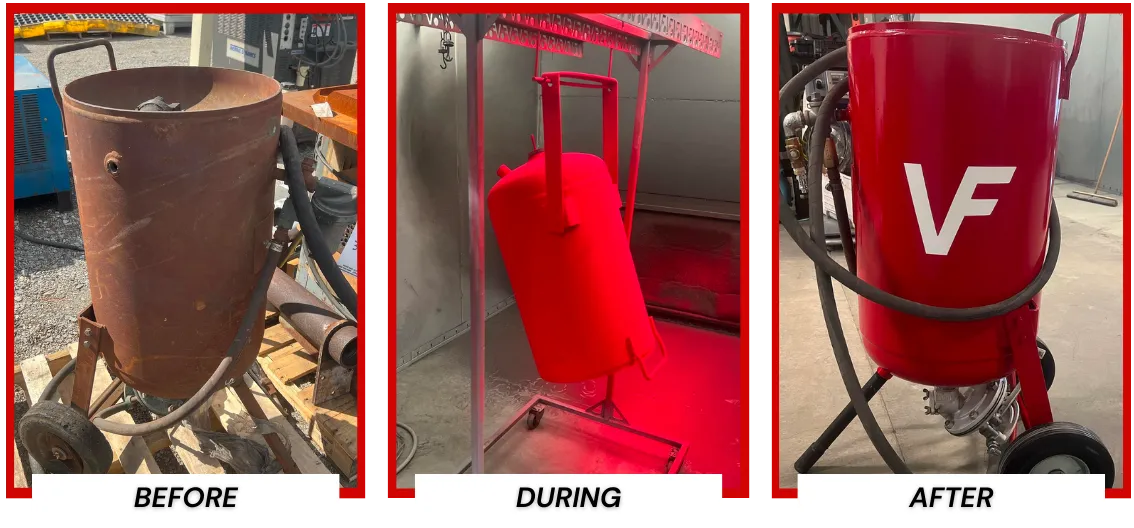

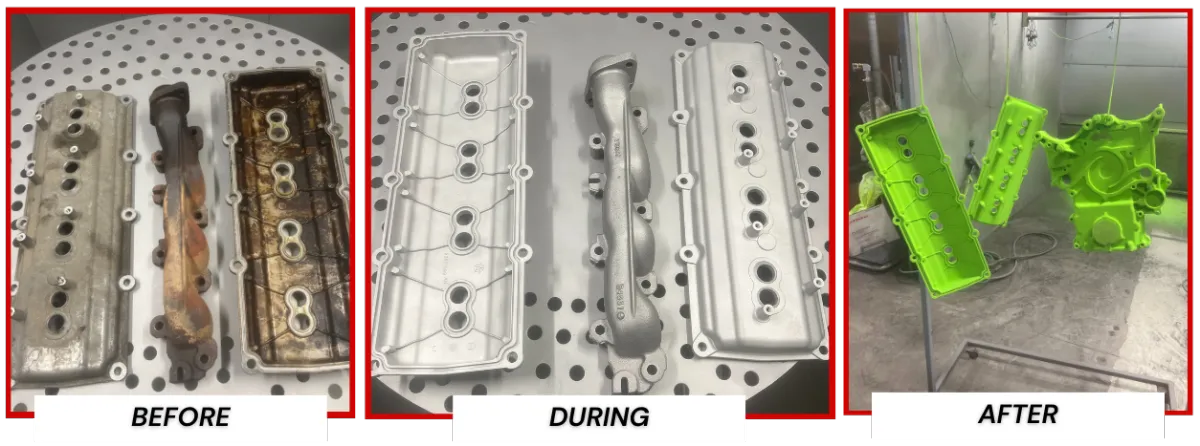

Projects

Before & Afters

A picture is worth 1,000 words...

Check out the project gallery with some of our favorites!

Testimonials

Our Client Reviews

We take pride in the positive feedback we receive, as it reinforces our commitment to providing top-quality product results, exceptional service, and expert advice. Your kind words inspire us to continue exceeding your expectations.

I can't say enough good things about Victory Fab & Powder Coat. They were recommended to me by a friend, and I couldn't be happier with their service.

JaneDoe

CEO Brand

When my metal parts rusted through, I thought I was in for a long, stressful ordeal. However, a quick call to Victory Fab & Powder Coat changed everything.

John Doe

Manager

I've been a loyal customer of Victory Fab & Powder Coat for years, and they never disappoint. Whether it's a metal sign for a gift or a complex part, their quality is always spot-on.

JaneDoe

Entrepreneur

The Mechanics

MEET WITH PROFESSIONAL TRAINER

At [Your Tire Shop Name], our team is the driving force behind our success. We take immense pride in introducing you to the dedicated individuals who make your tire-related dreams a reality.

John Doe

Mechanic

John Doe

Mechanic

John Doe

Mechanic

Copyright © 2026 Victory Fab. All rights reserved. Created by XXI Designs Corp.

Fine Print, Terms & Conditions and Privacy Policy