SERVICES

Pre-Treatment

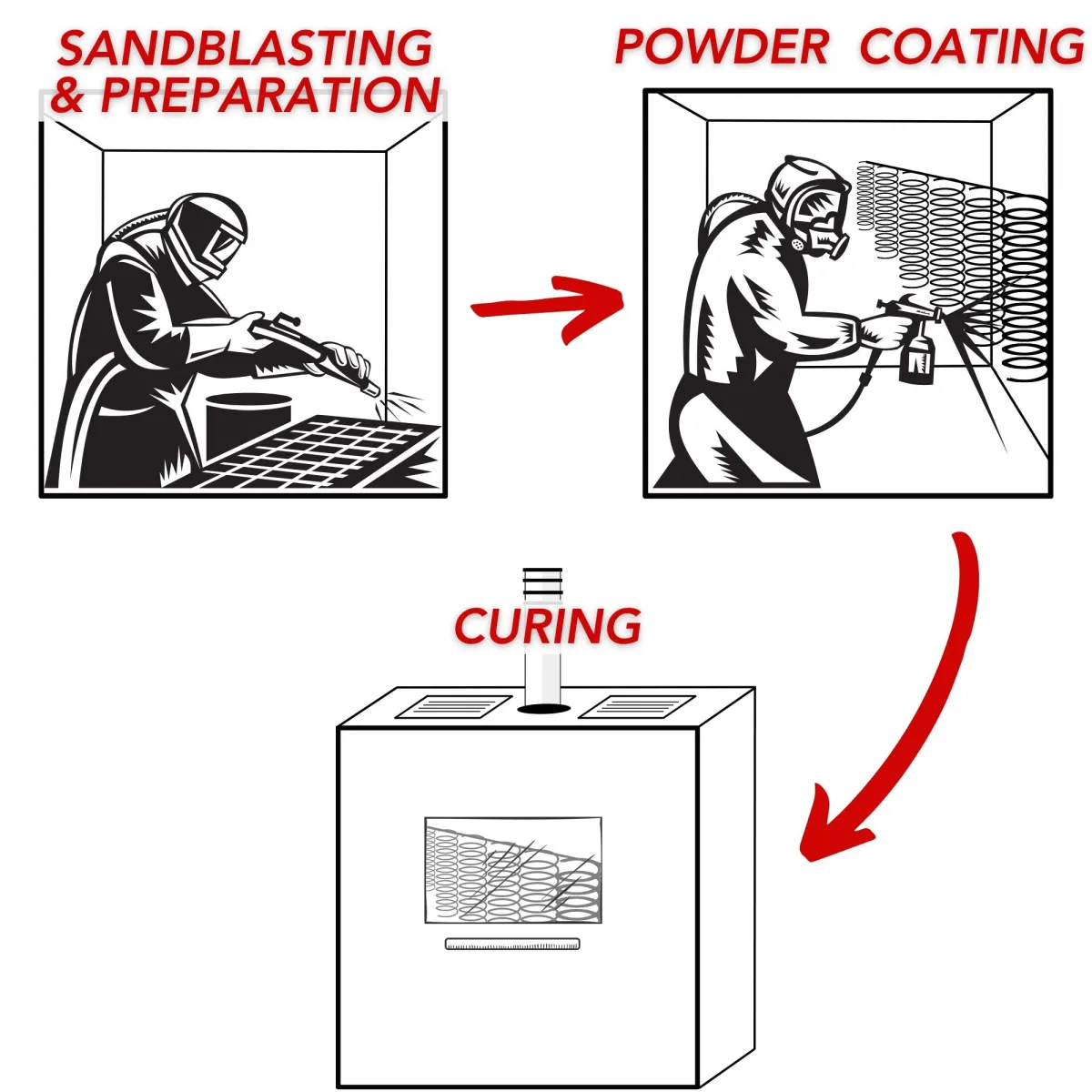

You may wonder if your project needs pre-treatment or not. While powder coating over an item that has not undergone proper pre-treatment may appear to be high-quality, the powder will chip and corrode easily, so all of our projects undergo pretreatment. While sandblasting is our preferred method, we evaluate each project and will discuss options and cost with you prior to beginning.

Sandblasting (or, abrasive blasting) propels a stream of abrasive material under high pressure to smooth out a rough surface, roughen a smooth surface, shape a surface, or to remove contaminants or coatings. Commonly used to remove rust, paint, or other residue, as well as to clean, degrease, and outgas the bare metal, sandblasting may also be used to change the condition of a metal’s surface, even removing scratches or marks. A high-quality sandblasting treatment will leave the surface clean, but slightly rough, providing a pattern for the powder coat to anchor to. You may hear this referred to as "tooth", as the coating mechanically interlocks (or "bites") into the metal.

Sand Blasting Services

While we use sandblasting as pre-treatment for our powder coating projects, we also offer sandblasting as a stand-alone service. We will adjust our process and the grit to the specifications of your project. For more information, click the "Get Estimate" button above and submit your specifications.

Powder Coating Process

Powder Coating is a metal finishing technology to protect and/or provide color and/or texture to metal decorations, parts, and more.

Available in almost a limitless array of colors and textures, performance technological advances have made powder coating a far superior option to painting. A dry finishing process, over 15% of the total industrial finishing market utilizes powder coating on an array of products. The high-quality, durable finish allows for improved efficiencies, maximized production, and even environmental compliance.

How It Works

The most common powder coating application process is environmentally friendly, cost effective, and provides maximum protection.

First, the metal item is pre-treated to prepare the surface for maximum adhesion. Then, the powder polymer resin is combined with a variety of other items, including the desired colors, and they are melt mixed, cooled, and ground into a uniform powder that has the consistency of common baking flour.

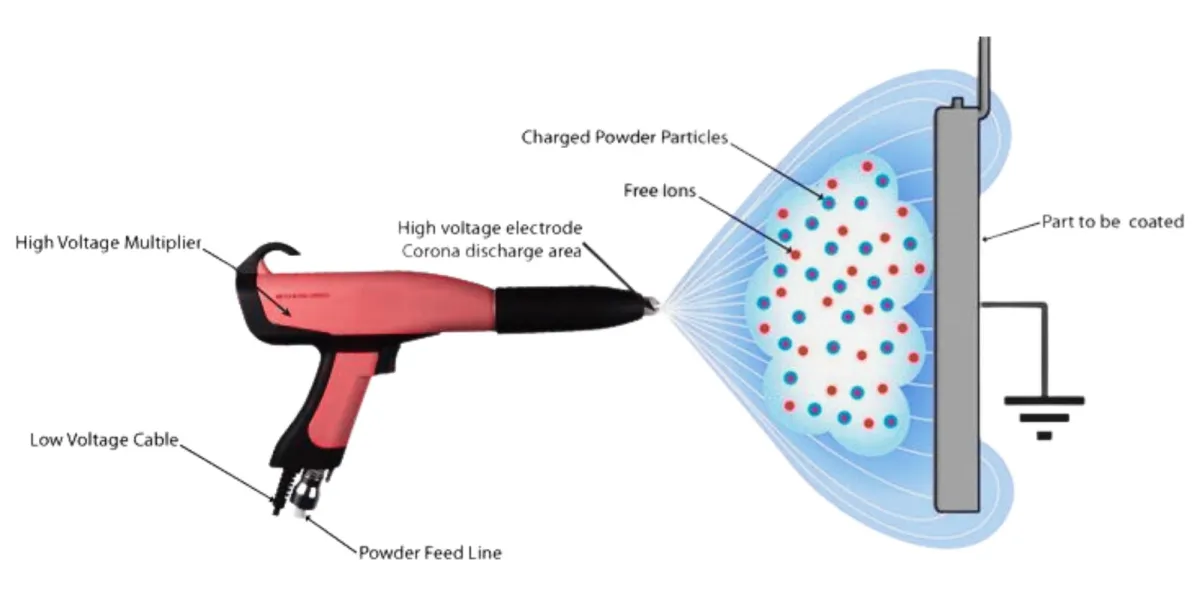

Then, the powder is applied to the item using electrostatic spray deposition (ESD). A spray gun that applies an electrostatic charge to the powder, making it attracted to the grounded metal item.

The parts then are cured in an industrial oven after the application is complete. In the oven, the powder coating undergoes a chemical process that bonds it to the metal, protecting it and making it incredibly durable.

Durability

Powder coating is commonly used as a higher quality alternative to traditional wet paints, including spray paint. It offers a more durable finish than paint, while resisting corrosion, scratches, chipping, and the impact of moisture, chemicals, extreme weather, and ultraviolet life. And, it creates a highly decorative finish as well as protecting tough machinery and machine parts that undergo the harshest of conditions.

Colors & Textures

At Victory Fab & Powder Coat, we utilize vibrant, high-quality powder coating finishes from premier industry manufacturers to bring your creative visions to life. With extensive experience in working with creative projects, you can expect personal attention to help you pick out the perfect color and texture for your project. We will ensure that your project is done to your specifications and stands out from the rest.

Victory Fab & Powder Coat is your trusted partner in bringing your visions to vivid reality.

The Mechanics

MEET WITH PROFESSIONAL TRAINER

At [Your Tire Shop Name], our team is the driving force behind our success. We take immense pride in introducing you to the dedicated individuals who make your tire-related dreams a reality.

John Doe

Mechanic

John Doe

Mechanic

John Doe

Mechanic

FAQS

What is the recommended tire pressure for my vehicle, and how often should I check it?

The recommended tire pressure for your vehicle can typically be found in the owner's manual or on a label inside the driver's door jamb. It's essential to check your tire pressure at least once a month and before long trips. Proper tire pressure ensures even wear, better fuel efficiency, and optimal handling, contributing to your safety on the road.

What's the difference between all-season and winter tires, and when should I consider switching to winter tires?

All-season tires are designed to perform well in various weather conditions, including light snow. Winter tires, on the other hand, have a specific tread pattern and rubber compound for superior traction in cold and snowy conditions. It's recommended to switch to winter tires when temperatures consistently drop below 45°F (7°C) to ensure better grip and control on icy or snowy roads.

How can I tell if my tires are worn out and need replacement?

You can perform a simple visual inspection and the "Penny Test" to check your tire tread. Place a penny into the tread grooves with Lincoln's head facing down. If you can see the top of Lincoln's head, your tire treads are too shallow and need replacement. Additionally, look for signs of uneven wear, cracking, or bulging on the sidewalls. If you notice any of these issues, it's time to consult a professional for a thorough assessment and possible tire replacement.

Copyright © 2026 Victory Fab. All rights reserved. Created by XXI Designs Corp.

Fine Print, Terms & Conditions and Privacy Policy